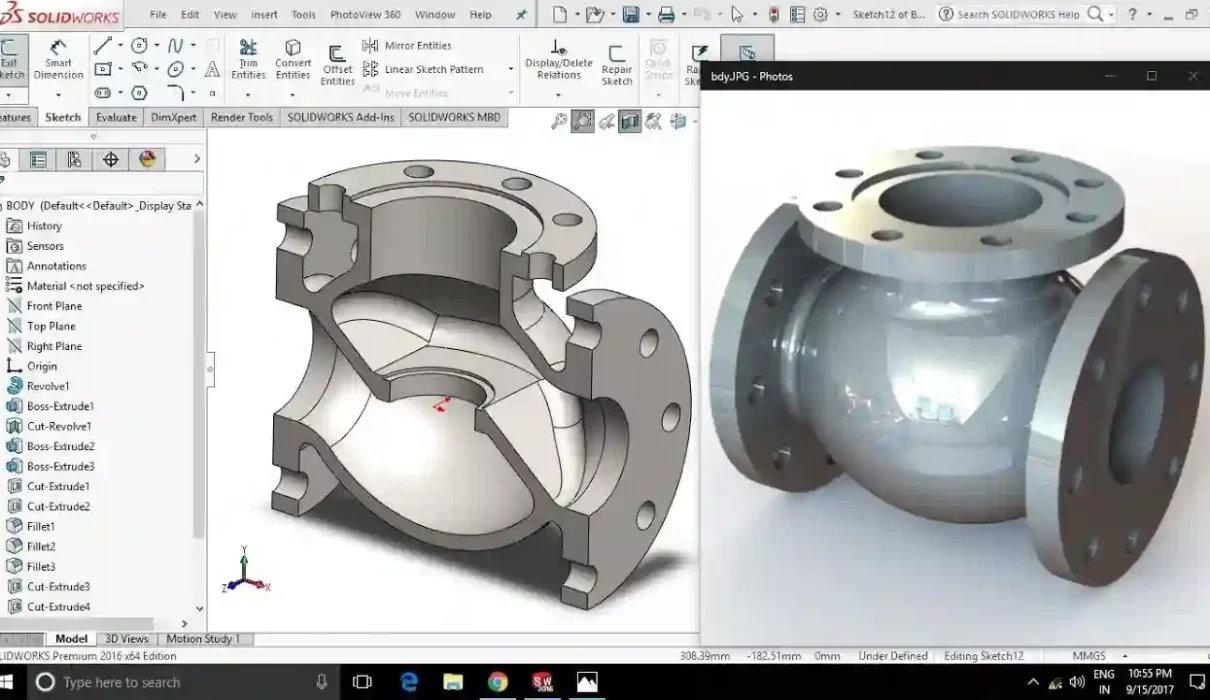

Do you know What is Check Valves? Check valves are designed to permit the progression of liquid across a pipeline framework or port one way as it were. They are receptive valves, implying that they are enacted by the sum and the crucial factor of the liquid present in the framework climate. These valves are normally utilized in discharge anticipation applications, flood avoidance conditions, and wastewater treatment elements.

In 1984, the Environmental Protection Agency (EPA) commissioned another sort of check valve, one that stood apart as a reasonable option to flapgate valves. The new valve included a duckbill-formed inward elastomer sleeve that reacted to changes in a liquid, pressing factor. Unfortunately, the valve sleeve shut because of discharge pressure, framing a tight seal obstructing debris from entering streams.

Further testing demonstrated that the duckbill-molded plan additionally offered unrivaled execution in toxin ensnarement, toughness, the halting of spillage, and different self-cleaning capacities. Presently, the duckbill elastomer check valve is regularly utilized in backwater counteraction and stream applications. The best state of the inside valve bill can routinely accomplish a tight shut position, giving a fantastic seal against debris in discharge applications. In addition, different duckbill models for bmw models have been designed for low pressing factor applications and contamination anticipation endeavors on bigger streams.

How does a check valve work?

Check valves are intended to react to pressure contrasts. For the duration of the existing pattern of the valve, there are examples where the critical factor of the liquids going through the valve is more noteworthy than the critical factor across the valve mechanism. For example, the power of upstream water makes a high differential pressing factor across the inside valve body, so the valve opens, permitting forward streams to go through. Notwithstanding, discharging water brings down differential pressing factors across the valve body, so the duckbill elastomer valve flexes shut, fixing debris out.

Present-day valves are designed to react to unobtrusive pressing factor changes. These more up-to-date valves react to slight changes in critical differential factors from forwarding or discharge, making them helpful for various conditions. Dissimilar to check valves with metal parts, for example, disk check valves, duckbill elastomer valves require fundamentally less support – they need inside metal parts that can rust or become eroded.

For what applications may check valves be utilized?

Duckbill valves can be utilized in an assortment of wastewater, stormwater, and discharge anticipation applications. One fantastic contextual investigation included a huge, notable retail location in St. Petersburg, FL. This store had a huge maintenance lake, or man-made lake intended to gather water.

Violent climate ended up being an issue for this store. During times of substantial downpour and high tides, the waters of Tampa Bay converse streamed into the lake, making the vegetation shrivel and bite the dust. As a result, the lake was fitted with three 36-inch check valves. Since these valves reacted to unobtrusive pressing factor differentials, they ended up being a fantastic arrangement in forestalling saltwater reverse.

Duckbill valves are reasonable for an assortment of different applications, also. For example, a few models are great for sewer vent and end-of-pipe outfall establishments. Others are introduced for the reasons for sewer framework control and sewer reverse anticipation. Still, others are utilized for stormwater control, as the retail location contextual analysis outlines; or, for wastewater treatment applications. Finally, certain duckbill models can be utilized in modern applications, such as destructive slurry, critical substance applications, and high-temperature compound responses.

The plan and design of duckbill check valves make them broadly relevant in constrained liquid conditions. The elastomer charge configuration is low-upkeep, without rust, and can be profoundly receptive to exceptionally real pressing factor changes across line liquid. In addition, these valves don’t need a force source or any outside activity to work. Thus, they are exceptionally adaptable and profoundly solid.